Laser 3D sensor

Our laser 3D sensors enable non-contact, one-shot measurement of the object's shape.

Automated shape measurement on production lines

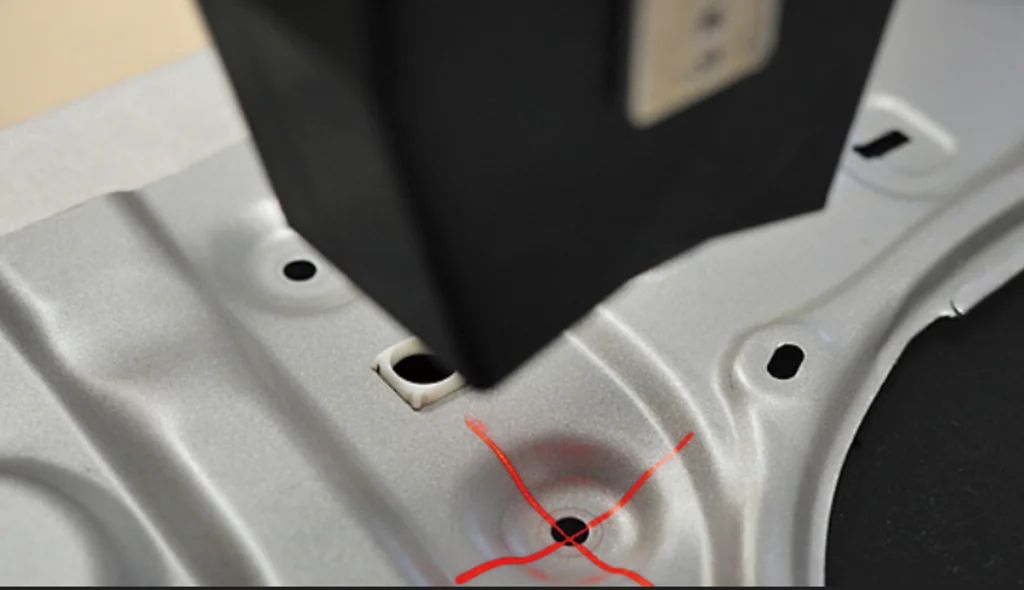

In the shape measurement of steel sheets in the production process, conventional methods make it difficult to carry out full inspection and numerical control due to variations in the operator's judgement. Our laser 3D sensors enable non-contact shape measurement and numerical control, which can be incorporated into presses and robots to realise automation and quality improvement.

Laser-based shape measurement

The optical sectioning method (triangulation by light-receiving part and laser) enables non-contact shape measurement. The object can be measured in a single shot.

Customisable and diverse applications

The measuring range and accuracy can be customised on request. As there are no moving parts, the system can be adapted to on-site environments such as factories. For example, it can measure the cross-sectional shape of pipes, half-pipes, etc., three-sided and three-column crossed structures, and the dimensions and positioning of holes, angles, steps and gaps. The sensors can also be mounted on robots and inspection jigs, making them suitable for a wide range of applications.

Product specifications

Example of product specifications (customisation is possible according to requirements and conditions of use)

| Equipment size | Φ:13 × L:218.5mm |

|---|---|

| Weight | 300g |

| Inner | diameter of the pipe to be measured |

| Shape of irradiating laser source | Ring laser |

| Laser wavelength | 635nm |

| Laser intensity | class 1M |

| Operating temperature | -10~45℃ |

| Measuring range | Radius 8 to 32.5 mm from sensor centre |

| Measuring field of view angle | 360° |

| Measuring time | 1sec |

| Measuring accuracy | ±0.2mm |

製品外形図

Product specifications